Aerospace Thermocouples Rated for Higher Temperatures

Aerospace-Sector Thermocouples Rated for Higher Temperatures

Thermocouples are versatile temperature sensing devices used in a wide variety of applications, from household appliances, to industrial furnaces to aerospace-related functions. Requirements for their temperature range varies significantly based on the application.

Within the aerospace industry, where the quality and reliability of components can literally be a matter of life and death, it is essential to use the most suitable equipment for these demanding environments. Given these stringent conditions, there are several reasons why as a best business practice, companies should source thermocouple assemblies, cables and wires from a reputable manufacturer that specializes in higher temperature applications.

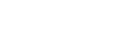

Role of an Autoclave in Aerospace Manufacturing

The aerospace industry is on a perpetual quest for efficiency, reliability and quality. Autoclaves are central to this mission, particularly when manufacturing large-scale components. With advancements in design, including automation and complex control systems, the need for reliable, high-quality sensing mechanisms increases in importance.

The large size of modern aerospace autoclaves, with some stretching up to 10 meters in length and 5 meters in diameter, emphasizes the scale of operations and the daunting challenge of accurate temperature sensing and measurements. Extensive literature available on the processing of composites using autoclaves underscores the industry’s reliance on these systems. Regardless of size and scale, the most important characteristics are precision and consistency. This is a situation when thermocouples rated for higher temperatures and challenging environments come into play.

Therefore, investing in high-quality, professionally designed, engineered and built thermocouple assemblies is not just a good practice, but a necessity.

Thermocouples Manufactured for High-Temperature Applications

Manufacturers such as TE Wire focus on certain industrial specifications with the goal of supplying the most advanced, effective and high-performance thermocouples that are tailored to the specific stresses and environments it will encounter. The resulting product development and available assemblies are therefore more aligned with the industry’s needs than a standard, off-the-shelf, catalogue, or in-house manufactured component.

TE Wire’s PEEKSense™ high-temperature thermocouple assembly is the only available solution in the marketplace that is non-fibrous for thermoplastic processing. PEEKSense represents a progression of the company’s popular AccuClave product line and is engineered specifically for high-temperature autoclave applications. It supplies the ability to endure temperatures up to 400 C for longer cycles.

The product is tailored for composite applications that rely on materials such as polyetheretherketone (PEEK), polyaryletherketone (PAEK), polyetherketoneketone (PEKK) and polyimide composites. These cables come in lengths between three and 100 feet, and conform to Special Limits ASTM E230/E230M, Class I IEC 60584 and BAC 5621.

The assembly consists of standard wire constructure of flame retardant applied liquid polyimide and it offers high tensile strength, chemical resistance and abrasion resistance—high standards for a thermocouple designed for a demanding industry.

The ability of PEEKSense to work with high-performance thermoplastics at elevated temperatures helps optimize the fabrication of aerospace composite parts. The thermoplastics used in composites -- PEEK, PAEK, PEKK and polyimide -- have particular characteristics that require specialized components to form parts with the highest levels of quality, consistency and reliability.

- Higher Curing Temperatures: Many high-performance thermoplastics require higher curing temperatures to achieve optimal mechanical properties that make them a preferable material for aerospace composites.

- Reduced Cycle Times: This ability to withstand higher temperatures for extended cycles means manufacturers can potentially reduce the overall cure time, leading to faster production and increased throughput.

- Consistency and Reliability: Accurate temperature readings throughout the process, supplied by a thermocouple assembly that retains precision performance despite the elevated temperature helps OEMs and operators achieve consistent processing for reliable parts performance. Temperature variations can lead to product defects or inconsistencies in the composite material, compromising finished part integrity.

- Cost Savings: A thermocouple rated for higher temperatures reduces the risk of equipment failure and subsequent and related cost of replacement or repairs. Furthermore, optimal cure conditions produce more consistent parts reducing waste for improperly cured parts that must be discarded.

- Versatility: Its compatibility across a wide range of high-performance thermoplastics allows for flexibility in the production cycle. Manufacturers can utilize different materials based on design specifications without worrying about or changing out the monitoring equipment.

As the aerospace autoclave produces composite components for the aviation industry, the role of the thermocouple cannot be underemphasized. Accurate temperature readings ensure components will be lightweight, strong and capable of withstanding the high stresses and extreme conditions of flight. Several types of composites form aerospace components, which is another reason why a thermocouple assembly with wide ranging versatility is key:

- Continuous fiber-reinforced composites

- Unidirectional tape composites

- Thermoplastic honeycomb sandwich structures

- Short fiber-reinforced thermoplastics

- Thermoplastic hybrid composites

AccuClave is the only proven solution that can consistently and reliably withstand the temperatures and pressures found in these aerospace applications.

TE Wire and Cable, renowned for its deep understanding of temperature’s pivotal role in operations, offers a comprehensive range of high-accuracy thermocouple wires and cables tailored for diverse temperature ranges. Products are meticulously tested and calibrated and backed by NIST-traceable standards. TE Wire offers a suite of customization options and ensures precision and reliability for any high-temperature application. Visit our product page to learn more about PEEKSense or give us a call to discuss your specifications for reliable temperature measurement in challenging applications.