Topics:

supplier relationships,

aerospace,

new year,

customer service,

composites curing,

Tradeshows,

SAMPE,

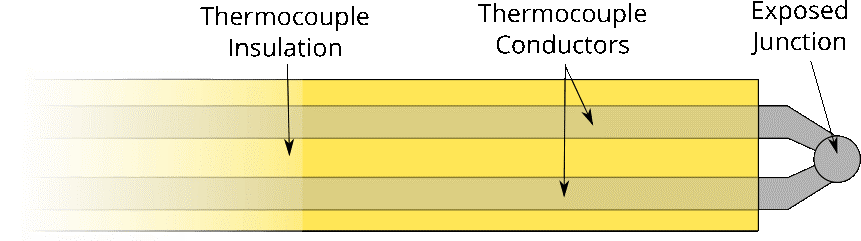

products

Posted by Corrie Hartline

March 7, 2022

Hooray! We finally get to see you in person! In two weeks TE Wire & Cable will be attending and showcasing our line of thermocouple products at the 16th Annual Wasatch Front Materials Expo in Sandy,...

READ MORE