Posted by Joseph Ugalde

May 17, 2019

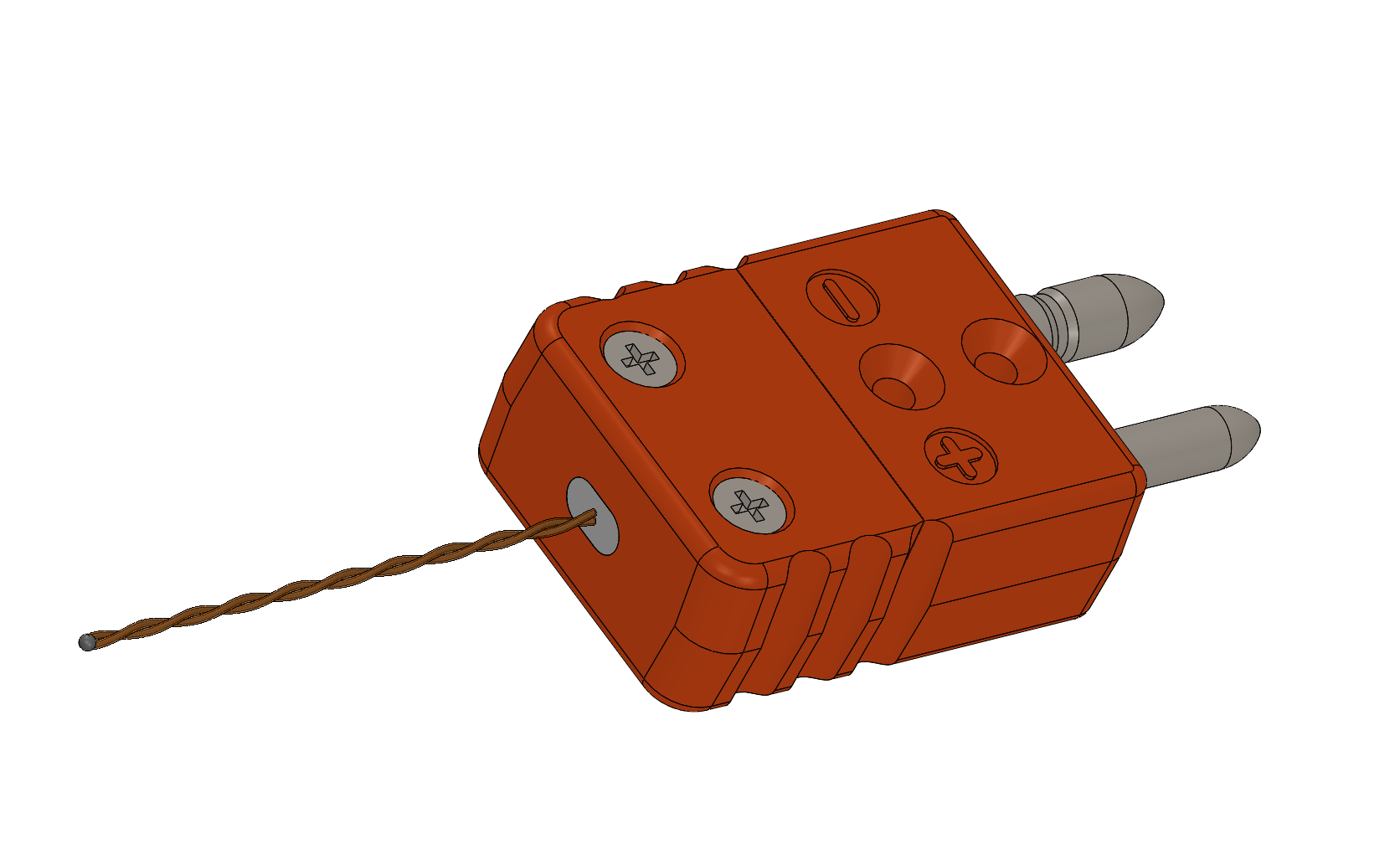

TE Wire & Cable prides itself on making quality high temperature products, meeting industry demand for innovative autoclave thermocouple solutions. Our AccuClave product line, which has been a staple...

READ MORE