Yesterday, I shared an infographic from SAMPE about the Seattle show coming in June. For many aerospace composites manufacturers, it is one of, if not THE tradeshow to attend each year.

I myself am looking forward to this year’s show. There will be a lot of cool things to see and who doesn’t love Seattle in the springtime?

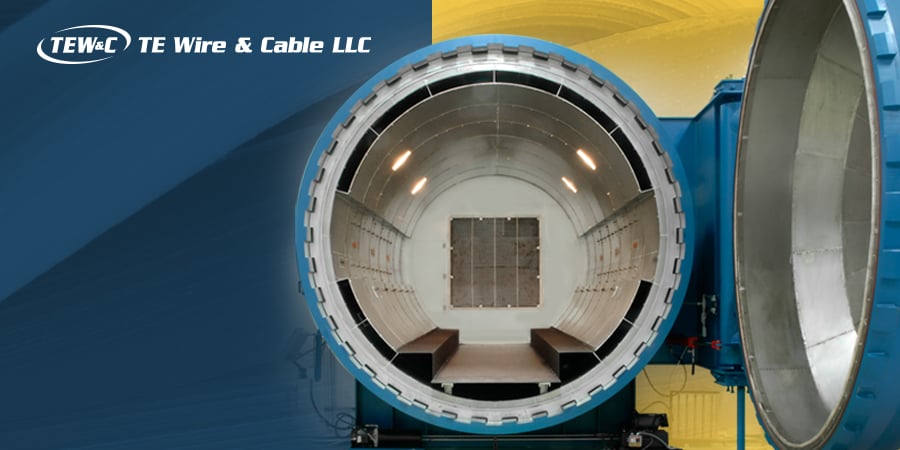

For years, our team at TE Wire & Cable has been working hard to provide composites manufacturers with thermocouple solutions for their aerospace autoclave applications. We’ve spent a lot of time with our customers, listening to the problems they’re facing on a daily basis. There are several that come up all the time.

Perhaps you’ve experienced these problems yourself:

- Inaccurate and unreliable thermocouple performance.

- Lost time and increased scrap due to poor junctions, loose connectors and leaks under the bag.

- Used thermocouples must be thrown away or undergo time-consuming and expensive refurbishing and testing prior to new cures.

- NADCAP audits.

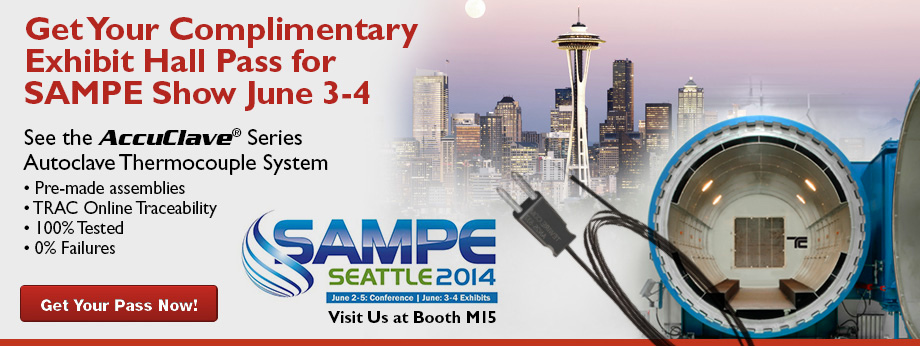

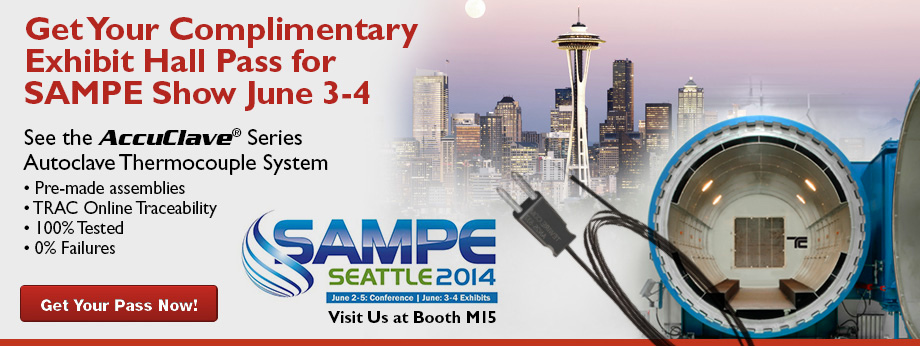

TE Wire has the solution for these problems and we’re featuring them in our Booth M15 on June 3-4:

- AccuClave® reusable, pre-made thermocouple assemblies

- AccuClave-X™ thermocouple extension cables for faster autoclave loading

- AccuConnect™ multi-circuit interconnect saves autoclave idle time

- AccuFlex™ patented technology for composite repairs with minimal mark-off

- TRAC online traceability simplifies NADCAP audits

For our current users of these innovative solutions, terms like 100% tested, zero (0)% failures and a proven ROI are all realities that keep them coming back for more.

Whether you’re a customer or not, I hope you’ll get a chance to visit us at SAMPE Booth M15 on June 3-4. For our customers, we’d love to catch up. Not a customer yet? Stop by and let us share with you how you can save time, money and reduce scrap in your autoclave operation.

During the show, we’ll work with you to calculate your ROI using the AccuClave family of products in your aerospace autoclave applications.

See you at SAMPE!