Posted by Vlad Fedorchak

March 11, 2015

Understanding Noise Levels and Installation Considerations

In part one, we discussed the four types of noise frequently found in instrumentation circuits (i.e., Common Mode, Cross Talk, Static and Magnetic) as well as the methods used to correct the problems they cause.

Next, we discuss the types of noise levels found in various environments and some installation considerations that will help you mitigate or completely eliminate the noise problems.

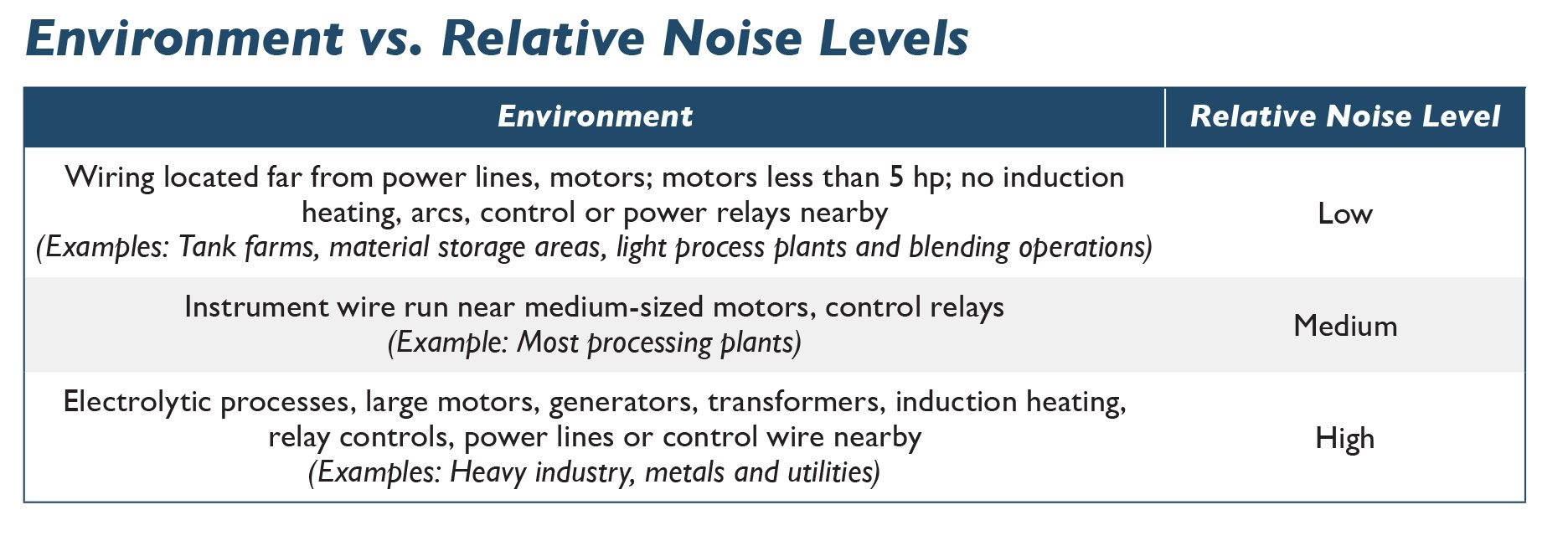

The table below classifies several environmental areas as having low, medium or high noise levels. This is intended to give a relative indication of how much noise is expected in a particular installation and how far to go in protecting against noise for the particular instrumentation circuits involved. As always, your results may vary.

Plant Installation Considerations

Besides the electrical problems that must be considered in choosing the proper wire and cable, you should also consider what a particular wire or cable installation must withstand from a mechanical standpoint. Here are a few to keep in mind:

Precautions to take during design

Precautions taken during design, engineering and installation can also reduce the effects of noise considerably. For example:

Ground Rules for Shields

Where shields are employed in both the single pair wires and in multi-pair cables for noise protection, there are some important ground rules to follow:

I hope this tutorial on how to control noise in instrumentation circuits has provided the level of detail you need to solve those pesky noise problems in your various applications. If you run into other types of problems or need further assistance, I welcome you to contact me. I’d be glad to help.

See also:

3 Basic Steps to Selecting the Right Thermocouple Wire for Your Application

Everything You Wanted to Know About Thermocouple Theory and Chemistry (but Were Afraid to Ask)