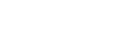

Overcome Autoclave Challenges with Thermocouple Technology on Display at SAMPE 2024

TE Wire & Cable is back at the annual SAMPE Conference and Exhibition (Society for the Advancement of Materials and Process Engineering). Look for our booth J15 at this year’s conference, May 20-23 at the Long Beach Convention Center in Long Beach, California, to view our advanced autoclave thermocouple technology, serving the aerospace industry for more than 7 decades.

SAMPE is North America's premier advanced materials and process engineering conference and exhibition. Each year, thousands of industry partners attend to find new materials, products and business solutions. As the sole technical conference and exhibition dedicated solely to advanced materials and processes, TE Wire staff exhibits annually to connect with its customer base.

SAMPE offers a prime opportunity to customers and professionals at the forefront of materials innovation to connect in person with the staff at TE Wire & Cable. At SAMPE 2024, TE Wire & Cable will showcase its innovative line of thermocouple products purposely engineered to overcome common autoclave challenges faced by composite manufacturers. Designed to withstand the extreme temperatures and process requirements of aerospace composite fabrication, these specialized solutions offer superior performance, traceability, and cost savings compared to traditional thermocouples.

- Our patented AccuClave® provide proven accuracy, reliability and ROI advantages over traditional thermocouple solutions.

- PEEKSense™ high-temperature wire provides exceptional heat resistance and durability for precision temperature monitoring.

- AccuFlex™ flexible vacuum-rated thermocouple assemblies ensure reliable temperature sensing, even on complex, curved surfaces.

At TE Wire & Cable, commitment to quality and innovation shines through in every aspect of its products, particularly in its thermocouples. One of the company's most significant features is the guarantee of 100% leakproof thermocouples, ensuring unparalleled reliability and safety in every application. What sets TE Wire & Cable apart is not only the superior performance of its products but also the transparency provided to customers. Through an online traceability system, customers can easily track the journey of their thermocouples from manufacturing to delivery, offering peace of mind and confidence in the quality and authenticity of its products.

Development of next generation aircraft and the safety and performance of today’s aerospace manufacturing relies on the optimized combination of advanced materials and reliable manufacturing processes, such as autoclave operations. Some of the key benefits that TE Wire's autoclave thermocouple assemblies deliver include:

- Consistent thermocouple performance with durable pre-made junctions

- Reduced scrap and downtime from loose connectors or bag leaks

- Simple replaceability without refurbishing or retesting

- BAC 5621 compliance and traceability for efficient NADCAP audits

- Labor savings from faster, easier installation

- Long-term cost savings from more reliable, consistent production output

Whether you're manufacturing aircraft structures, engine components, UAVs (uncrewed aerial vehicle) or satellites, having the right sensors and wire is critical for achieving optimal composite part quality. TE Wire's products provide the heat resistance, mechanical strength and longevity required for these demanding thermal processing applications.

TE Wire & Cable looks forward to seeing you at booth J15 to talk about the success other manufacturers have experienced using TE Wire autoclave solutions. If you can't make it to SAMPE, visit the aerospace industry page to see the full line of products that serve aerospace applications and to download data sheets on the industry’s best-performing thermocouples and accessories for aerospace autoclave operations.