Temperature Measurement with Expendable Load Thermocouples in Aerospace, Metallurgy Applications

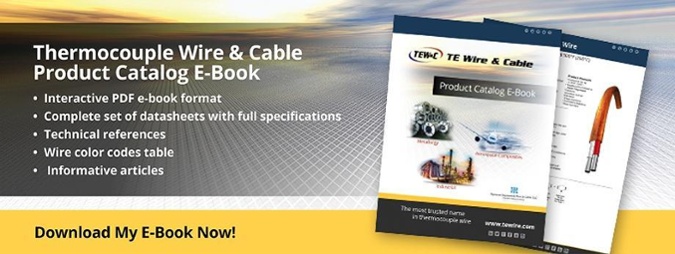

In heat treatment applications there are two important considerations concerning temperature: the furnace temperature and the load temperature. Both are measured with thermocouples. These thermocouples are often referred to as control and load thermocouples.

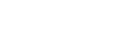

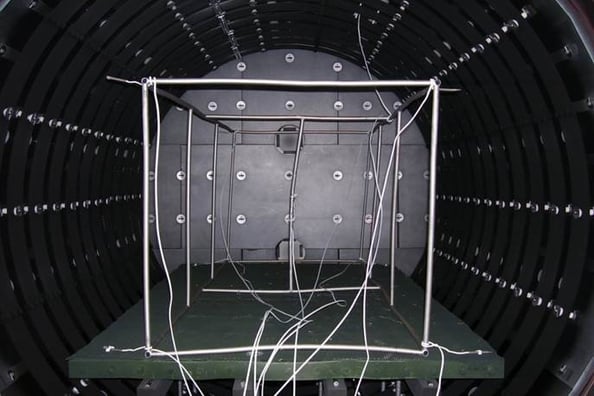

Very accurate high temperature thermocouple wire is attached to a reusable TUS fixture that replicates the maximum size of a load that could fill the furnace. Temperatures are then measured to insure that all of the zones and spaces inside the furnace reach temperature uniformity.

The heat treatment process is used on metallurgy applications, including titanium, aluminum, steel and other alloy materials to achieve certain mechanical properties. By using the heat treatment processes properly, manufacturers can provide the material with specific hardness, give it strength and reduce residual stress. The process, especially for aerospace composites applications, requires precise control of temperature over the heating cycle and sometimes through multiple zones.

Aerospace Material Specification, AMS2750 Rev E, covers pyrometry requirements for thermal processing equipment used in heat treatment.

For the purpose of this blog, we cover only the load temperature sensors and the importance they play to ensure that the finished products meet the applicable specifications. Temperature sensors are covered in Section 3.1 of AMS 2750E.

A few important definitions and tables within AMS2750E pertaining to expendable load sensor includes:

|

2.2.2 |

BASE METAL THERMOCOUPLE: Thermocouple whose thermoelements are composed primarily of base metals and their alloys. Examples of base metal thermocouples include E, J, K, N, and T. |

|

2.2.18 |

EXPENDABLE THERMOCOUPLES: Thermocouples made of fabric or plastic covered wire. The wire is provided in coils or on spools. Insulation usually consists of glass braid, or ceramic fiber cloth on each conductor plus glass braid overall. |

|

2.2.27 |

LOAD SENSORS: Sensors that are attached to or in contact with production material, a representation of production material, or are buried in the load of production material and which supply temperature data of the production material to process instrumentation. |

|

3.1.2.6.1 |

The Maximum amount of wire/cable in a roll at the time of calibration shall be as follows: point c. Base Metal Secondary Standard Sensors: 2000 feet (610 m) point d. All Other Base Metal Sensors: 5000 feet (1525 m) |

||

|

3.1.2.6.3 |

The roll calibration method shall not be used if the difference between the highest and lowest calibration readings of the sample thermocouples at any calibration temperature exceeds the following requirements. |

||

|

|

3.1.2.6.3.1 |

1°F (0.6 °C) for primary and secondary standard thermocouples. |

|

|

|

3.1.2.6.3.2 |

2°F (1.1 °C) for system accuracy test, temperature uniformity test, controlling, monitoring, recording, and load thermocouples. |

|

|

3.1.2.6.4 |

For rolls not meeting 3.1.2.6.3 |

|

||

|

|

3.1.2.6.4.1 |

It is permissible to divide the roll into shorter length rolls that do not meet the end to end tolerance difference specified in 3.1.2.6.3 |

||

|

|

3.1.2.6.4.2 |

It is permissible to use individual thermocouples from the roll if they are calibrated in accordance with Table 1. |

||

TABLE 1 (pg 34) - SENSORS AND SENSOR CALIBRATION - States the maximum permitted error and certification intervals for sensors.

TABLE 2 (pg 35) - THERMOCOUPLES AND EXTENSION WIRE - Specifies alloy information and ANSI ASTM E230 color codes for thermocouple types. However, color codes in accordance with other national standard(s) maybe be used.

AMS2750 Rev E is a detailed document and compliance with these standards is critical to success of your heat treatment operation and the proper selection of equipment and temperature sensors that will do the job. For a copy of the complete specifications, visit http://standards.sae.org/ams2750e/

At TE Wire & Cable, we closely monitor these requirements, verifying that we’re compliant throughout our high temperature expendable thermocouple product line.

Important Questions You Need to Answer

Whether you're considering our CEFIR®, HG–Vitreous Silica, or Q-Glass products, to make sure that you get the right thermocouple product for your heat treatment process, be prepared to answer the following questions:

- Is compliance with AMS2750E standards a requirement for you application?

- Do you require the wire to be calibrated at specific points?

Maximum calibration intervals per AMS2750E is 250°F.

- What length is required?

- Base Metal Secondary Standard Max length per spool is 2,000 ft.

- Do you require 1,000 ft or 5,000 ft?

- Do you need spool end-to-end tolerance 1.0°F for primary and secondary standard thermocouples? Or 2.0°F for system accuracy test, temperature uniformity test, controlling, monitoring, recording, and load thermocouples?

- Are pigtails on the inside of the spool required for incoming calibration inspection?

How Can We Help?

Once you have these answers, our knowledgable team is here to assist you with the final selection of the RIGHT high-accuracy thermocouple for your application.

By the way, we will be at several tradeshows in September and October. If you're going to be attending, why not set-up an appointment to meet with us to discuss your applications and any challenges you face? Just click the link below for the show you'll be attending. When you schedule an appointment, we'll be sure to save some swag for you!

- Titanium 2016 - Sept 25-28 - Phoenix, AZ (Booth 415)

- CAMX 2016 - Sept 27-29 - Anaheim, CA (Booth N52)

- FNA 2016 - Oct 4-5 - Nashville, TN (Booth 531)

We look forward to seeing you!