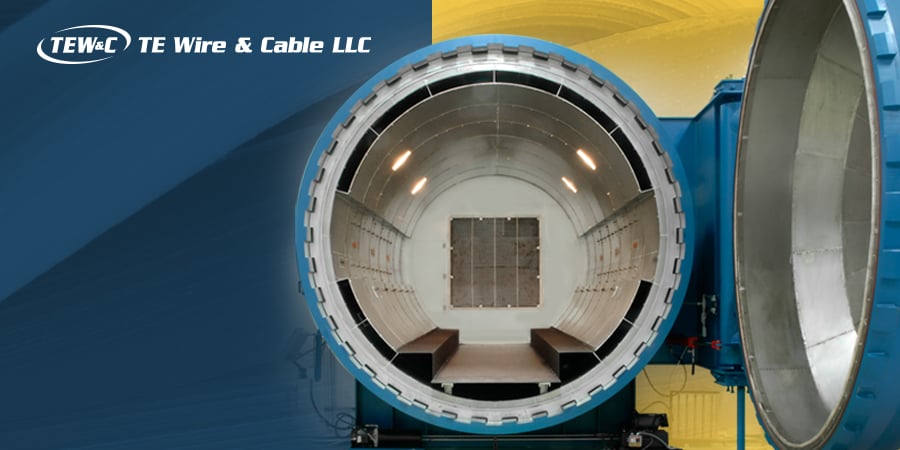

TE Wire to showcase high accuracy thermocouple wire and cable solutions for metallurgy applications at Furnaces North America 2014

In the steel and aluminum industry, high-temperature metallurgy applications demand high-accuracy monitoring. Thermocouple wire is a key component in temperature monitoring and measurement. To assure final product quality and energy savings, this wire must be as reliable and accurate as the overall monitoring system.

At TE Wire, we don’t care how much you turn up the heat because we know how to handle the intense temperatures in metallurgy applications. Using our in-plant ISO17025 accredited calibration lab, we develop thermocouple wire and cable products that deliver exceptional performance and help our customers meet global quality standards.

Learn more about our robust high temperature thermocouple solutions at this upcoming show:

Our thermocouple wire and thermocouple extension cable solutions are ideal for the following metallurgy applications: component testing, heat treatment, furnace surveys and metals production. For a product preview, explore the following TE Wire solutions:

- CEFIR® Series ceramic fiber—up to 2400°F (1316°C)

- Vitreous silica fiber—up to 2000°F (1100°C)

- Q-Glass high-temperature fiberglass—up to 1600°F (870°C)

- G-Glass fiberglass—up to 1200°F (650°C)

- FEP fluoropolymers—up to 500°F (260°C)

- PVC polyvinyl chloride—up to 221°F (105°C)

Don’t miss this great opportunity to learn about our industry-leading expertise and thermocouple wire products that are ideal for demanding metallurgy applications. See you at Booth #531 at Furnaces North America 2014!

For more information about TE Wire’s various thermocouple solutions, download our FREE Wire & Cable Line Cards.

To schedule a meeting at Furnaces North America 2014 to further discuss your application, please contact us via email or call 888-483-9473.

Also see: Does your thermocouple wire measure up to global standards for aluminum heat treat?