Dr TC's Cure for Autoclave Thermocouple Reversed Polarity

It’s the ugly stuff bad dreams are made of: You load up your parts in the autoclave or curing oven and then plug the thermocouple wires into the jack panel.

Everything looks good and the door closes.

Oh no! Not again!

As the temperature starts to rise, the software detects a thermocouple anomaly. One TC is not tracking the temperature profile. In fact, the reading becomes significantly ‘bad’ as the temperature climbs.

Maybe you are lucky and you can live with one or two TCs being software disabled. Or maybe you need every TC reading to be correct in order to produce a part.

Then a shrill noise over your shoulder – could it be the program manager screaming about scrap and engineering tags?

Nope, it’s your alarm and you wake up from this dream before it becomes expensive with lost cures, parts, time and labor.

Unfortunately, this dream is not that far from reality for some managers. And, to make matters worse, this ugly dream-sequence-turned-reality can rear its ugly head over and over again. What could have happened?

If I were your Doctor of Autoclave Thermocouples (no need for formalities, call me Doc), I would put my stethoscope on the thermocouple plug.

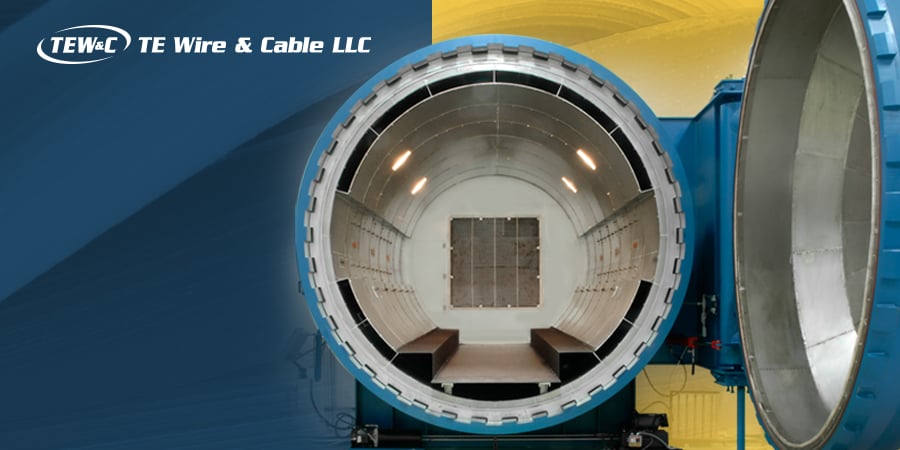

A close examination might indicate a serious problem called “Reversed Polarity”. Simply stated, a thermocouple consists of two wires each with differing metal content. Industry nomenclature calls one wire the positive wire. The other wire is the negative wire. These two wires generate a very small voltage or EMF that is proportional to the temperature being measured.

The clave instrumentation connected to the thermocouple is ‘looking’ for an input voltage established upon the correct polarity of positive wire to positive input and negative wire to negative input. If the wires are hooked up in Reverse Polarity the instrument does not detect the reversal and displays the temperature reading as if the circuit is hooked up correctly.

So maybe you don’t think that a thermocouple hooked up in reverse will affect the output in a meaningful vector reading. Table 1 below will change your mind forever.

Table 1. Type J special limits of error thermocouple

Table 1. Type J special limits of error thermocouple

Actual reading at temperatures used in composite cures

Some think that reversed polarity will indicate the exact algebraic opposite and therefore an operator can quickly discern the problem.

If only it were that easy.

As you can see from the table, the reversed polarity reading is seriously incorrect and not the exact opposite.

There are two prescriptions that will provide you with a cure.

1. Thermocouples assembled in house

If you make or repair your own autoclave thermocouples, you will need instrumentation and a testing protocol to determine the connection is correct (i.e., the positive wire is connected to positive pin and negative to negative). Even then, it is just as important to have a second and separate test to insure that the first test was done correctly.

Why a second test? Isn't that overkill? Not at all. In my experience, having visited with many users making their own thermocouples, they frequently admit that they often find bad thermocouples even after in-house testing. Hey. Nobody's perfect. And we're all human, so we make mistakes. I can be far too easy to get distracted and distractions can result in the error of reversed polarity to slip through in the assembly and testing process. So, the lesson is, if you want to eliminate the potential for an error slipping through, do the second test.

2. Premade themocouple assemblies

Rather than having to do twice as much testing to guarantee no errors make it into the clave, consider using premade thermocouple assemblies. TE Wire & Cable's patented AccuClave products eliminate the potential for reversed polarity100%. The AccuClave manufacturing cell in our plant does have humans who do a fantastic job. We also have computer-controlled final QC test stations. The computer does not take coffee breaks, sneeze, or think about fantasy football team standings or girls night out. Every finished product is tested by a computer for a number of parameters including reversed polarity -- before it ships out. Only if every computer test is passed with 100% approval will the product be laser etched with unique TRAC traceability number and go into our packaging area for shipment.

Using the AccuClave product line will insure that your reversed polarity issues become a nightmare no more.

You may even sleep better and for certain your management will be happier – assuming that's possible.

Future Dr. TC cures will cover vacuum leaks through thermocouple wires and other topics

Don't forget: This doctor makes house calls. You can send your questions to me or request an appointment any time.

Click here to receive your own doctor’s prescription and evaluation the ROI of your autoclave composites manufacturing operation.

Learn More:

Dr TC's Cure for Erratic Temperature Reading in Autoclave Composites Manufacturing

Four Ways to Meet Increased Demands on Aerospace Autoclave Applications